Customization is standard to us

Every year we produce thousands of special solutions and have developed a streamlined process

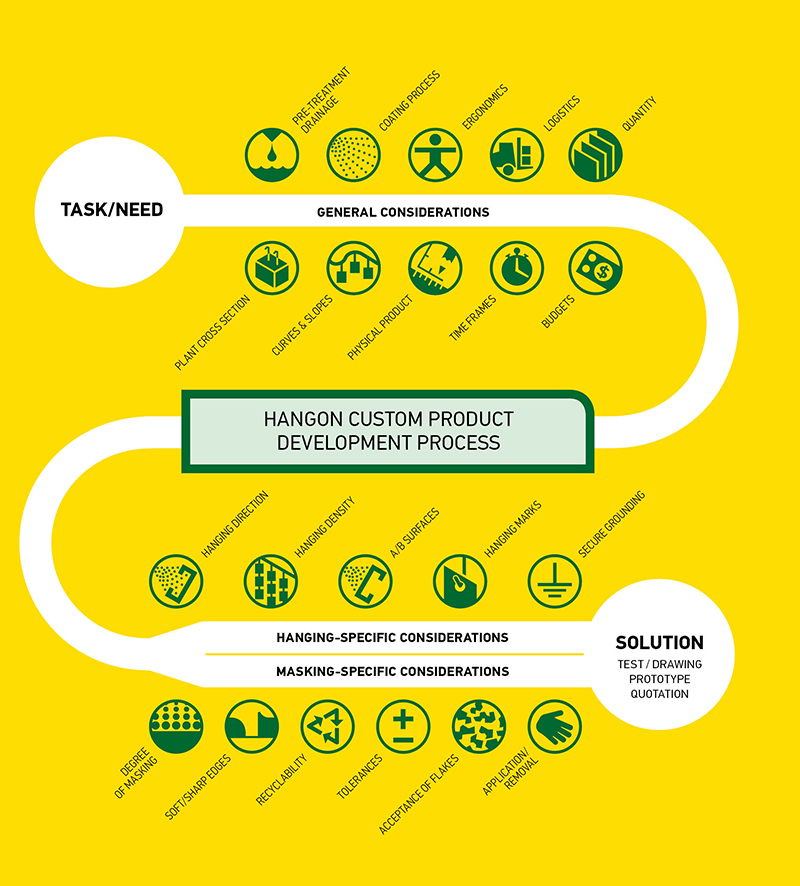

- HANGON CUSTOM PRODUCT DEVELOPMENT PROCESS

As experts in our field, we are highly knowledgeable about every tiny detail of the industrial coating process. Our R&D department has decades of experience to develop specialized solutions for the coating industry.

Listening closely to your needs and gathering the necessary information enables innovative and smart solutions. We analyse how various tasks in your specific coating process can be solved in the best possible way. Finding the smartest solution for your individual needs may take time – but our experience is that every hour invested pays off through long-term profitability.